Measuring and providing real-time Biochemical Oxygen Demand (BOD) and Chemical Oxygen Demand (COD) data to a central SCADA control system has been impossible, until now. After 18 months of trials, presentations and formal approval processes the first Proteus was permanently installed on the inlet to a WWTW between the primary settlement tanks and the aeration lanes. A true milestone for providing real-time BOD data to control WWTWs anywhere in the world.

Proteus

The Proteus represents 5 years of intensive, peer-reviewed research and development to prove that it was possible to measure BOD/COD/TOC/DOC and coliforms in real-time using a completely different measurement technique than what other manufacturers have tried to use to date. The patented Proteus is based on a variety of highly specialist fluorometers and complex algorithms that can measure these parameters but also compensate for interferents at the same time. Unlike many manufacturers we have ensured that our R&D is internationally peer-reviewed as we fully understand that the breakthrough that this technology represents is beyond what most people can readily believe without significant proof.

A Story of Successful Innovation

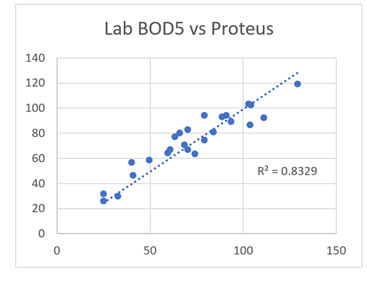

The STW Innovation Department were first approached in early 2018 and after formal agreements a very specific and authoritative set of tests were undertaken at their Spernal WWTW which is used as a working test site for all new innovative technologies. A 3-month trial involving 70+ samples and 30,000 individual BOD and COD readings was carried out with comprehensively decisive data proving that the Proteus was able to measure BOD and COD accurately and reliably with the minimum of maintenance. All of the supporting evidence and data was reviewed by STW and subsequently the Proteus was formally made available company-wide for monitoring and controlling BOD and COD in real-time. The Proteus represents the first instrument that STW have ever approved for monitoring BOD or COD in real-time.

Further research undertaken at various WWTWs within STW at Primary Settlement Tanks and Final Effluent points has shown how reliable the Proteus is for monitoring BOD/COD but has also highlighted how inaccurate BOD5 manual sampling is. This has been a show-case of innovation for STW in that a completely new technology has been allowed to prove itself in front of a water company and break barriers that nobody thought was possible. To most measuring BOD would seem impossible but thanks to the partnership and innovation between Proteus Instruments and STW, it is now possible for STW to roll this technology out across the company to save £millions associated with energy savings, maintenance savings and other efficiencies in the process. Furthermore, it will ensure that water companies can operate WWTWs more efficiently and ensure better compliance. This may mean that the operation of some WWTWs can be relaxed whereas with others it may need to be tightened. The Proteus simply improves the ability to control most processes within a WWTW.

Activated Sludge Process Control

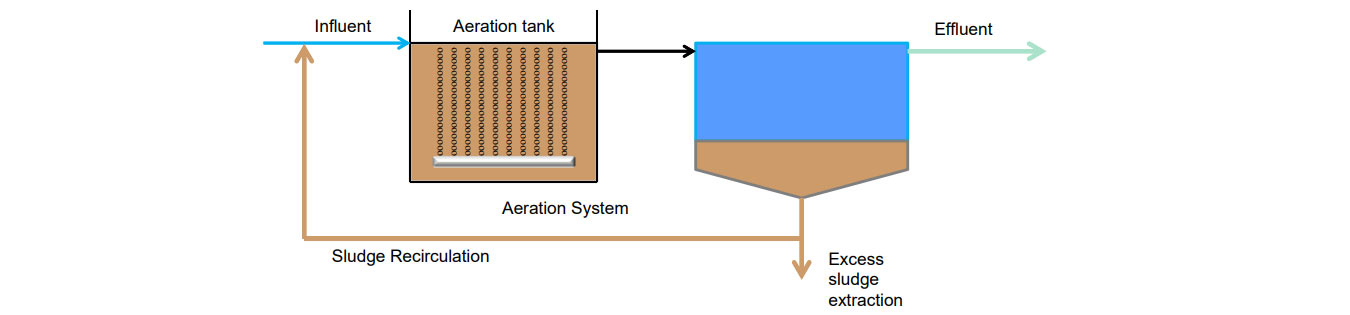

STW requested that the Proteus was installed at the head of the Activated Sludge Process in order to be able to control, optimise and maximise BOD/COD/NH4 removal and ensure nitrification. Raw sewage is initially screened and after primary settlement the flow is passed forward to the ASP process where air is fed through a set of diffusers through the effluent. This essentially breaks down the solids into a slurry creating a bacterial soup which digests the pollutants. The combination of raw sewage and biological mass is often referred to as a Mixed Liquor.

STW requested that the Proteus was installed at the head of the Activated Sludge Process in order to be able to control, optimise and maximise BOD/COD/NH4 removal and ensure nitrification. Raw sewage is initially screened and after primary settlement the flow is passed forward to the ASP process where air is fed through a set of diffusers through the effluent. This essentially breaks down the solids into a slurry creating a bacterial soup which digests the pollutants. The combination of raw sewage and biological mass is often referred to as a Mixed Liquor.

Installation

RS Hydro (UK Distributor for Proteus Instruments) supplied and installed a small control panel on the side of the ASP Inlet whilst the Proteus was suspended from a support arm over the channel.

RS Hydro (UK Distributor for Proteus Instruments) supplied and installed a small control panel on the side of the ASP Inlet whilst the Proteus was suspended from a support arm over the channel.

With the control panel already assembled and tested prior to install, the whole system, including the Proteus was installed within one day. The client specification was to have multiple 4-20mA outputs and a health status:

- BOD

- COD

- Ammonium (NH4)

- pH

- ORP/REDOX

- Turbidity or TSS

- Temperature

Although this system is AC-powered, the Proteus can be installed almost anywhere in the world with minimal power consumption; this means that it can be installed to provide near real-time data using the smallest of solar panels (5-watt). However, this installation is required to provide real-time 1-second data to STW’s local SCADA system and as such RS Hydro assembled a complete control panel to facilitate this. All measurement control is provided by the embedded micro-controller and fully-functioning PLC logic. As well as transmitting continuous data both the controller and Proteus have also been set to record every 5-minutes. You can never have too much data but essentially serves as a backup to the SCADA system. The live data will allow STW to monitor the actual real-time carbonaceous load coming into the works and to control downstream processes more efficiently. It is specifically engineered to use the data to directly control the variable speed drives connected to the ASP blowers. The expected energy saving is thought to be very considerable. We have calculated that the typical energy savings for a 100,000 population WWTW would pay for the Proteus within 6 months. In addition, this doesn’t take into account the substantial savings the Proteus provides over other water quality instruments with regards to wear & tear and general maintenance.

Maintenance & Cleaning

The Proteus for this location has been programmed to provide 1-second data with intermittent cleaning using its integral brush/wiper system. Despite being in one of the worst environments possible the integral cleaning system ensures that the Proteus optical lenses are kept clean at all times. When the cleaning system is active the live readings are momentarily frozen to ensure there are no false readings. In terms of maintenance apart from calibration (typically only every 6-12 months for optical sensors), the wiper/brush sets only need to be replaced every 6-months which typically takes just a few seconds. Therefore running costs and maintenance activities are negligible. This means that the Proteus can be installed in harsh environments without concerns of fouling.

The Proteus for this location has been programmed to provide 1-second data with intermittent cleaning using its integral brush/wiper system. Despite being in one of the worst environments possible the integral cleaning system ensures that the Proteus optical lenses are kept clean at all times. When the cleaning system is active the live readings are momentarily frozen to ensure there are no false readings. In terms of maintenance apart from calibration (typically only every 6-12 months for optical sensors), the wiper/brush sets only need to be replaced every 6-months which typically takes just a few seconds. Therefore running costs and maintenance activities are negligible. This means that the Proteus can be installed in harsh environments without concerns of fouling.

Calibration

The Proteus is fully calibrated in the factory prior to installation but a local calibration is recommended to not only ensure that the Proteus is accurate but also to provide confidence to the local operators that the Proteus is truly capable of measuring BOD/COD in real-time. Once installed it is recommended that a quick local calibration is done by taking paired and timed wastewater samples. The averages of these paired samples will then be correlated against the Proteus data to provide a local calibration which will then be stored in the Proteus. This local calibration an be done remotely depending on whether the calibration is stored in the Proteus or the telemetry unit so hence it would not be necessary to revisit the Proteus. We recommend that routine local calibrations are updated on a yearly basis which is an easy undertaking.

The Proteus is fully calibrated in the factory prior to installation but a local calibration is recommended to not only ensure that the Proteus is accurate but also to provide confidence to the local operators that the Proteus is truly capable of measuring BOD/COD in real-time. Once installed it is recommended that a quick local calibration is done by taking paired and timed wastewater samples. The averages of these paired samples will then be correlated against the Proteus data to provide a local calibration which will then be stored in the Proteus. This local calibration an be done remotely depending on whether the calibration is stored in the Proteus or the telemetry unit so hence it would not be necessary to revisit the Proteus. We recommend that routine local calibrations are updated on a yearly basis which is an easy undertaking.

It’s all about the data…

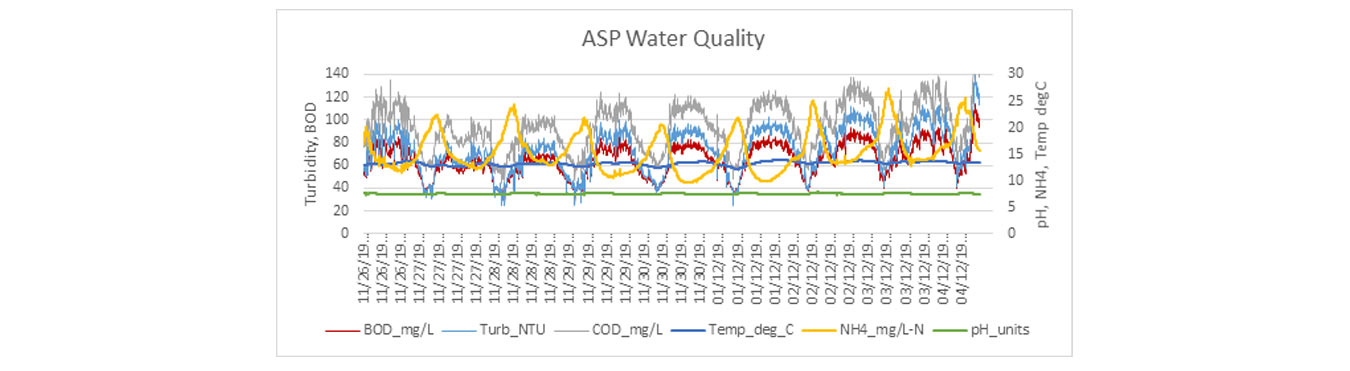

As you can probably imagine there are not many occasions where you can view trended BOD or COD data but this is certainly one of them. Very few of us have had the experience of witnessing such data and how it inter-relates with the more classic parameters such as turbidity, ammonium, dissolved oxygen, pH or ORP.

Being able to monitor and observe BOD/COD with the Proteus allows operators to view their process in real-time; it is also therefore possible to share it internally or externally. Once the readings are captured by STW’s SCADA system the data can be used almost anywhere in the WWTW. This could mean that multiple processes could be controlled from a single measurement point irrespective if those processes involve upstream or downstream assets or indeed whether they are within the WWTW itself or in the sewerage network.

The trend below shows the diurnal patterns of BOD, COD, NH4, turbidity, pH and temperature over a 10-day period. Alternative instrumentation suppliers can only offer DO or NH4 probes to help control aeration blowers but using a Proteus will allow WWTW operators worldwide to optimise the usage of their aeration blowers and therefore contributing to very significant energy/cost savings.

Conclusions

For the UK the next Annual Management Plan (AMP7) from April 2020 will focus heavily on instrumentation and control of WWTWs. It is clear that the Proteus can be an integral part of affording more control to operators of these WWTWs. The associated benefits of controlling WWTWs are potentially exponential in terms of energy savings and maintenance savings. Beyond that, efficiently operating WWTWs will ensure for a better environment, they will be able to process more wastewater therefore reducing the amount of time they discharge to rivers during storm events. Furthermore, the Proteus can aid with the design of WWTWs as they can be used as a survey or design tool for building new WWTWs or indeed deciding the level of remedial work that would be required to improve a WWTW’s efficiencies.

The ability to share the data externally also enables better co-operation between different environmental, industrial and regulatory organisations, encouraging close, inter disciplinary partnerships. For example, coliform monitoring at one location in a river or bathing water could be shared between dozens of different user groups or communities to inform them whether it is safe to use the water.

The ability to share the data externally also enables better co-operation between different environmental, industrial and regulatory organisations, encouraging close, inter disciplinary partnerships. For example, coliform monitoring at one location in a river or bathing water could be shared between dozens of different user groups or communities to inform them whether it is safe to use the water.

In a world where the population is continuously increasing and the environment under threat, responsible operation of WWTWs and co-operation further afield is critical; the Proteus is a key step in achieving this goal with ease and efficiency.